UV DTF Printing: Everything You Need To Know

What is UV-DTF Printing?

UV Direct-to-Film (UV DTF) printing is a modern, advanced transfer technology that uses UV-curable inks to print designs onto transfer film. UV DTF printing creates durable, scratch-resistant stickers, making it ideal for branding and personalising items such as tumblers, glass, metal, wood, plastic, ceramics, and acrylic.

Unlike traditional DTF printing, the UV-DTF printing process eliminates the need for a heat press, making it easy to apply transfers to all shapes and sizes. Transfers can be printed as standard smooth stickers or raised, 3D-effect and textured stickers by adding more layers of ink and varnish to your design.

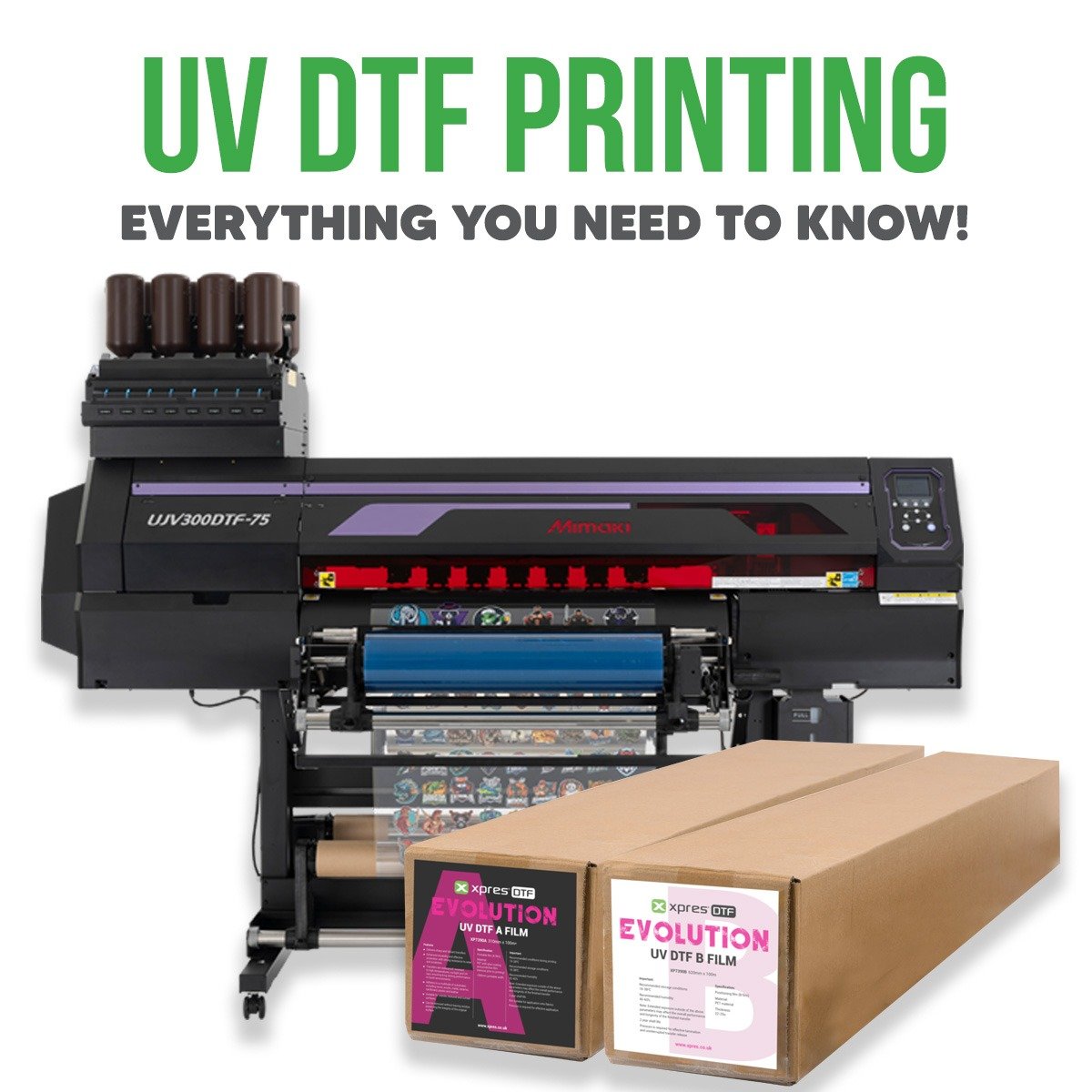

Mimaki’s First UV-DTF Printer

Mimaki's first UV-DTF printer brings the UJV300DTF-75, which produces vibrant, durable transfers for curved or uneven surfaces. Its dedicated film system, stable media handling, and next-generation UV inks ensure bright, long-lasting results, while the user-friendly design makes customised goods production simple and efficient.

Features & Benefits of the UVJV300DTF-75

- Easy to use and reliable

- Personalise objects unlimited by size or shape

- Compact and efficient

- Automated inline lamination

- No weeding required for faster production

- One-touch media loading

- Specialised film handling rollers

- Next generation UV curable inks

- RasterLink7 software included

Unlimited By Shape Or Size

Go beyond the limits of traditional printing and bring vibrant, detailed graphics to wood, acrylic, curved metal, leather, and even rigid plastics. From bespoke gifts to prototypes and limited-run products, you can print directly onto almost any surface and achieve stunning results every time.

Helmets

Mugs

Wine Glasses

Skateboards

Flower Pots

Electrical Devices

Mimaki’s UV Ink is Formulated for Performance

Mimaki's new UV inks have been formulated to be completely free of SVHCs and CMRs, thereby reducing their impact on human health and the environment. Designed for both performance and safety, ELH (hard ink) offers high scratch resistance, while ELS (soft ink) ensures excellent flexibility. Together, they provide outstanding versatility across a wide range of substrates and applications. These inks support advanced, sustainable and safe printing without compromising on quality or functionality.

Xpres DTF Evolution is Now Available for UV DTF

Tried, tested, and trusted, Xpres Evolution UV Film makes UV-DTF printing an easy and efficient process. The newly released A and B films must be used together as a matched system to ensure seamless production and optimum transfer performance. Compatible with the Mimaki UVJV300DTF-75, Xpres Evolution UV film provides everything you need for UV-DTF printing.

How UV DTF Works

The A Film is made up of 3 layers: a carrier film, an adhesive layer and a protection film. The protection film is removed before printing to expose the adhesive. Your designs are printed directly onto the adhesive layer, and the printer cures (hardens) the inks as it goes, while also bonding the inks directly to the adhesive. Because the ink cures immediately, varying ink volumes can be applied across the design, allowing for textured finishes and a premium 3D, raised effect that sets UV DTF printing apart from traditional transfer methods.

As Film A exits the printer with the cured design in place, Film B is laminated over the adhesive and transfers to encapsulate and protect them while also providing a release/application tape layer, which is essential for applying the stickers to the intended substrate.

Once laminated, the transfers can be cut into individual stickers ready for application. When ready to be applied, peel the B Film away from the A Film, which will lift the transfer (with adhesive) away with it. The transfer can now be applied directly onto the chosen surface. Position the transfer and apply even and firm pressure during application. It's always best practice to apply the transfer from its centre first and, using your fingers and/or a felt squeegee, work the transfer onto the substrate from the centre outwards to help reduce bubbles and improve edge retention. When in place, remove the B Film, leaving the sticker on the substrate. Any bubbles caught under the sticker can be removed by making a pin hole in the bubble and working the air out using your fingers or a felt squeegee.

Are you ready to explore what UV-DTF printing can do for your business? Discover our UV DTF hardware and consumables or get in touch with our expert team today.

FAQs: UV DTF Printing

Can you print UV DTF on a regular printer?

No, most standard inkjet printers use dye-based or pigment inks, which are not compatible with UV technology. You need a UV flatbed printer or a UV-compatible printer that supports UV-DTF films.

What equipment is needed for UV DTF?

- UV-DTF Printer

- UV Film A & B

- UV Inks

- Felt Squeegee (Recommended)

What is the lifespan of UV DTF prints?

UV-DTF transfers are extremely durable. In usual conditions and with the correct care and process of UV DTF printing, you can expect your transfers to last up to 5 years.

Why is my UV DTF peeling?

Peeling can occur if the design wasn't pressed down firmly enough, especially the edges. To prevent peeling, we recommend using a felt squeegee to make sure all the transfer is pressed onto your product.