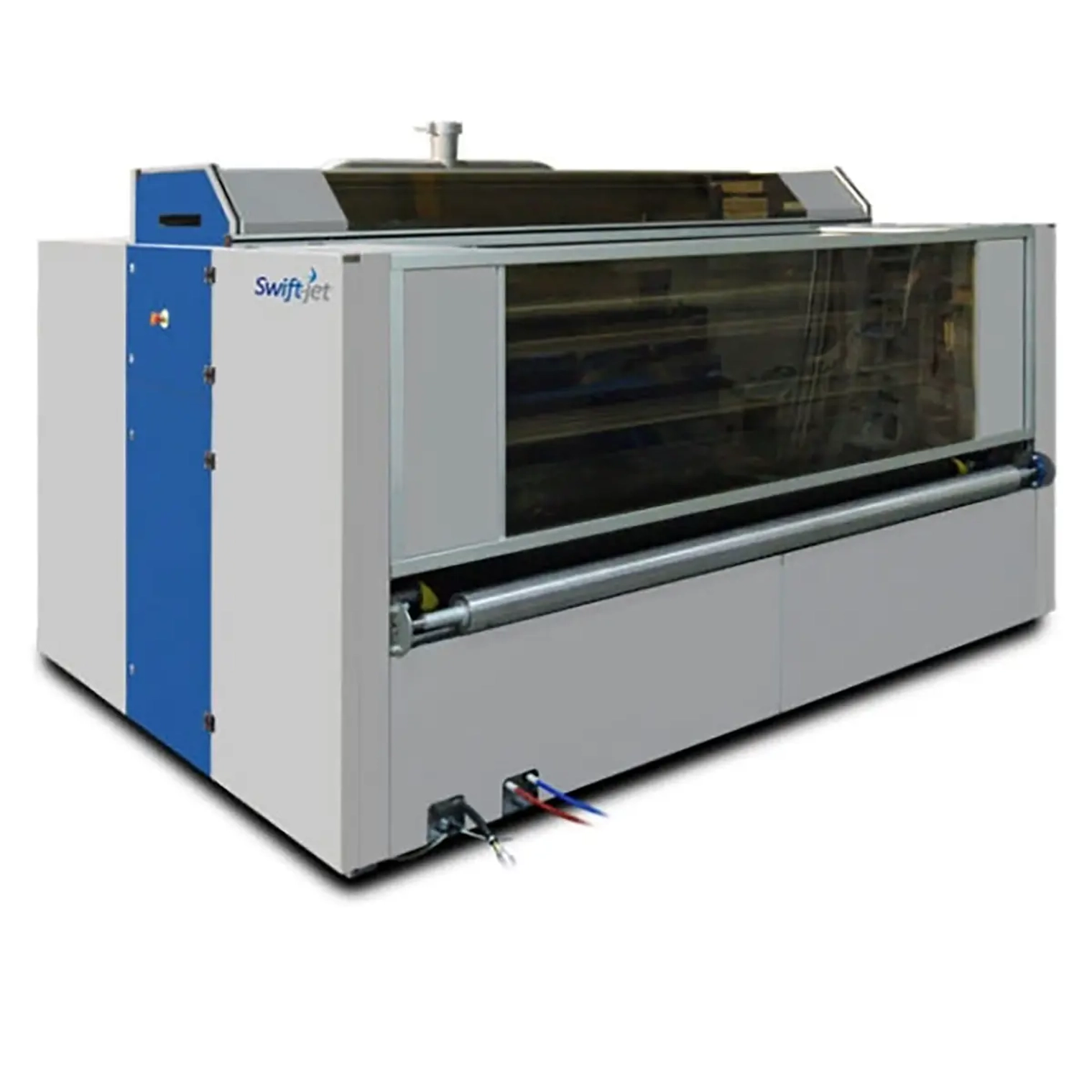

Swift-Jet

Swift-Jet provides an on-demand application process for digital print preparation, with rapid start and stop. Following surface cleaning, the machine uses a patented high-pressure spray technology to apply a consistent application of pre-treatment chemistry to PFP fabric. It then undertakes a drying process using its unique, patented, scanning drying technology before presenting the fabric for printing. All processes are contactless with full digital control for exacting results and optimum performance.

It can be used as a stand-along machine for pre-coating reel-to-reel or inline directly with a digital print machine. The mechanical and software design ensures consistent performance at variable process speeds to match today’s industry standards for digital print processes.

Swift-Jet offers matchless process savings, with significant reductions in water, energy and chemical consumption. The typical payback period is under 2 years with savings on processing costs from Day 1.

Out Of Stock

The potential annual savings when operating Swift-Jet compared to conventional textile process methods:

- Water saving: 65 tons

- Equivalent energy savings: +700,000 KWH

- Chemicals savings: 7 tons

Calculation based on 1 million m²/annum

A single-sided spray application is used, which allows for reformulation of pre-treatment recipes. This results in reduced water, drying and energy.

Application rates are uniformly controlled with the ability for fine level adjustments and an overseeing software control system.

An alternative Infrared wavelength combination coupled with high velocity impingement air and vacuum extraction has created a truly unique drying process. This is matched perfectly to the application rates, ensuring energy consumption is minimised whilst maximising performance and process control.

Features:

- Contactless application

- Start and stop on demand

- Rapid response to process requirements

- Reduced printing faultsVariable application rates and fabric penetration levelsHigh pressure sprays with controlled droplet size

- New concept in Infrared drying

- Award winning design developmentsInternational patents and IP pendingDramatically reduces energy consumption