aeoon Kyo Link DTG Printer

The future of DTG printing

The Kyo Link Series is for companies that aim to work with the most technologically advanced DTG printers on the market and we’re delighted to have a demo unit in our customer showroom.

It connects complex front-end interfaces with demanding back-end processes, can be linked with a wide variety of applications and uses the most modern RIP software. The Kyo Link Series allows effortless connections to a homepage, online shop and API interfaces. Further highlights are an integrated projector, scanner and heat press with which R2P materials can be pre-pressed. Of course, in addition to the smooth human-machine interaction, as with all aeoon printers, you achieve unrivalled production capacities with the highest quality print results.

The Kyo Link Series is therefore the most suitable printer for companies with high production volumes and automation requirements.

Kyo Link DTG Printer

For the future-oriented DTG printing

The Kyo Link Series is for companies that aim to work with the most technologically advanced DTG printers on the market and we’re delighted to have a demo unit in our customer showroom.

It connects complex front-end interfaces with demanding back-end processes, can be linked with a wide variety of applications and uses the most modern RIP software. The Kyo Link Series allows effortless connections to a homepage, online shop and API interfaces. Further highlights are an integrated projector, scanner and heat press with which R2P materials can be pre-pressed. Of course, in addition to the smooth human-machine interaction, as with all aeoon printers, you achieve unrivalled production capacities with the highest quality print results.

The Kyo Link Series is therefore the most suitable printer for companies with high production volumes and automation requirements.

Output 12/3 - on a dark garment

Print size (40x20cm/ ~16x8n)*

Depending on the perfomance of the operator, on the material and design.

180*

Pieces per hour* (average)

Benefits

Latest software version

Visualisation for each print job on an extra screen

Job scanner for each print station

Improved automation functionality

Improved integrations platform

No use of pretreatment on white garments – for low print costs

Integrated heat press for pre-treated T-shirts, max. size 40 x 50 cm

Industrial print heads with a print resolution from 600 dpi up to 2400 dpi

Integrated beamer

Integrated OPC-UA interface

Thomas Dress, CEO & Founder of Smake®

"Smake® recommends the Kyo Link series especially for POD customers with one-offs. The additional features, such as the integrated scanner, pro-jector and heat presses for pre-pressing R2P shirts or freshly pretreated textiles, provide the perfect base for integrating the Link into a fully automated production process.”

Compact - Highlights at a glance

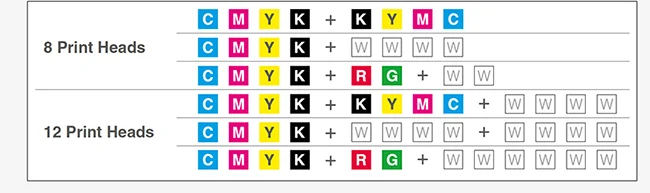

Ink Channel Configurations

Get in touch

Are you interested and want to find out more?

We are happy to advise by phone or email, call 01332 85 50 85 or email aeoonsales@xpres.co.uk.

Finance Calculator

Finance options are available for this product. These may vary on a case by case basis and should be discussed with a member of the Xpres team.

Xpres are not the lender, but are acting on the customers behalf to arrange contact between our finance partners.

| Weekly Equivalent | £86.77 |

|---|---|

| 24 Monthly Payments | £375.99 |

| Total Cost | £9023.76 |

| Tax Relief @ 19% | £1714.51 |

| Cost of Finance | £7309.25 |